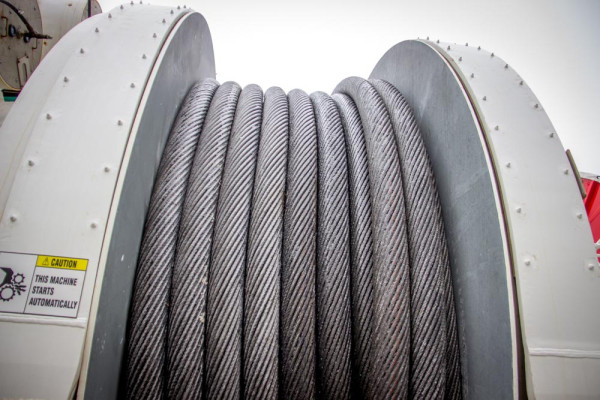

Namibia leading in Marine Diamond Recovery

News

Discover the most recent developments and exciting updates from Debmarine Namibia by exploring our latest news and events.

Empowering young San women through collaboration

14 Dec 2023

Debmarine Namibia and the Ongula Homestead Skills and Technical Education Academy joined forces to provide training for 10 young San.

The intense competition featured a gripping homestretch duel, with Earl Cardigan emerging victorious against strong contenders.

We handed over 12 toilets valued to the Nicolas Witbooi Memorial School situated near Dordabis in Khomas Region with the

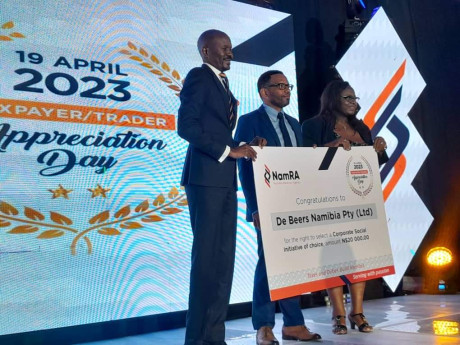

Top Taxpayer in the Country

24 Apr 2023

Debmarine Namibia has been recognised as the top taxpayer in the country

We recently sponsored several equipment to support skills development worth N$200 000 in Keetmanshoop in ||Kharas Region

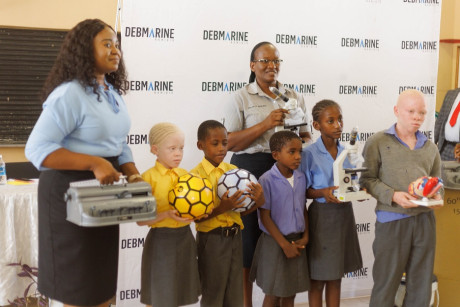

School equipment for a special school

22 Mar 2023

We recently sponsored school equipment to Eluwa Special School in the Oshana Region. The school harbours three special s

N$3.2 million investment in Netball Namibia

06 Jun 2022

This year, Debmarine Namibia is further committing to a total investment of N$3.2 million to Netball Namibia to keep the